Military Applications

When extreme conditions are expected, Fiber-Tech panels are requested.

Whether we are keeping our military tools, equipment and ammunition dry & secure with fiberglass reinforced plastic panels in containers & shelters, or whether we are protecting our troops from gunfire, blast fragments & shrapnel, Fiber-Tech’s complete line of composite panels has the solution.

Fiber-Tech’s custom built manufacturing equipment has combined the benefits from several types of manufacturing processes in a proprietary process of heat accelerated vacuum assisted infusion. This process utilizes the common materials specified by many government agencies and produces a high quality extremely durable fiberglass reinforced panel by evenly distributing the thermoset resin into the fiberglass woven roving fabrics.

Ballistic Panels, E-Glass, and More

Choose from Fiber-Tech’s wide variety of composite panel configurations which have been proven in numerous military applications around the world. Military applications have included…

- Walk-in coolers

- Kitchen & cooking quarters

- Laundry

- Restroom facilities

- Medical units

- Offices

- Storage & transport facilities

- Communication & command posts

- Overhead cover systems with armor panels

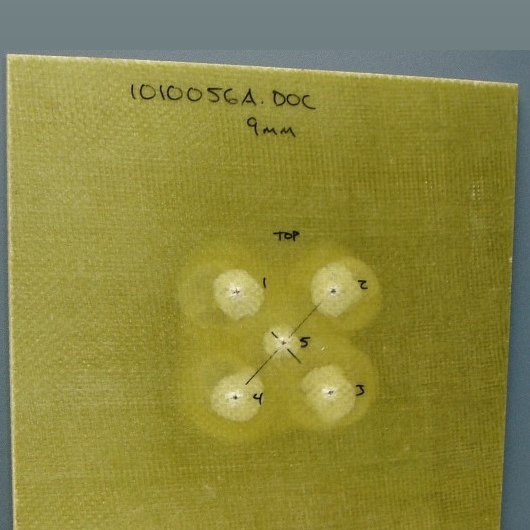

E-glass armor ballistic panels are also commonly specified for protection of our troop’s camps and out-posts. Fiber-Tech’s armor ballistic panels meet or exceed the most commonly seen military specification UL 752 Level 3 threat level protection. Fiber-Tech proudly meets many of the threat levels defined by National Institute of Justice (NIJ) and the Underwriter Lab (UL) threat level scales.

Utilizing the e-glass woven roving or special armor ballistic fiberglass, Fiber-Tech’s unique manufacturing process properly wets-out the woven roving fiberglass with minimal resin to reduce the finished weight of the panel and to assist in reducing the panel costs. Our high capacity manufacturing plants in Ohio and Washington can handle extremely high volumes in very condensed schedules. There is no job to small or too large!

Contact Fiber-Tech for Fiberglass Panels for Military Application

Fiber-Tech is the leading manufacturer of fiberglass panels for the transportation, construction, corrosion, military, shelter and marine markets.

Call the “Composite Panel People”at Fiber-Tech Industries today!

Download Information Sheet for ARMOR BALLISTIC Fiberglass Panels

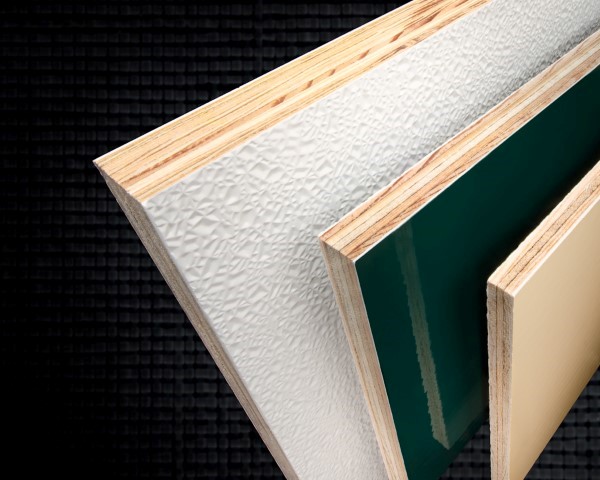

Download Information Sheet for CLAD TUFF® FRP/Plywood Panels

Download Information Sheet for CLAD FOAM® Insulated Foam Core Panels

Download Information Sheet for Honeycomb Core FRP Panels