The Fiber-Tech FRP Panel Advantage

Fiber-Tech’s proven manufacturing process combined with our choice of the finest raw materials has allowed us to serve numerous industries for over 40 years. Industry leading manufacturers of premium & specialty trailers, truck bodies, houseboats, containers and shelters have chosen Fiber-Tech’s structural fiberglass reinforced panels over other types of panels due to the numerous benefits.

Fiberglass panels from Fiber-Tech have a variety of advantages and benefits over our competitor’s products. There is a reason why top-tier manufacturers and OEM’s consistently choose Fiber-Tech for their FRP panel needs. FRP panels and fiberglass panels from Fiber-Tech offer many unique consumer-driven benefits. Some of the major benefits of FRP panels are listed below.

Advantages of Fiber-Tech's FRP Panels

- Structural fiberglass panel – Not a laminated glued skin to core

- Seamless, one-piece panel construction

- Ease of graphic installations

- No mold releases or waxes

- Durable, strong & abuse resistant

- Choices of colors, sizes, and thicknesses

- Decades of proven performance

- Optional core materials available

- High volume capacity capability

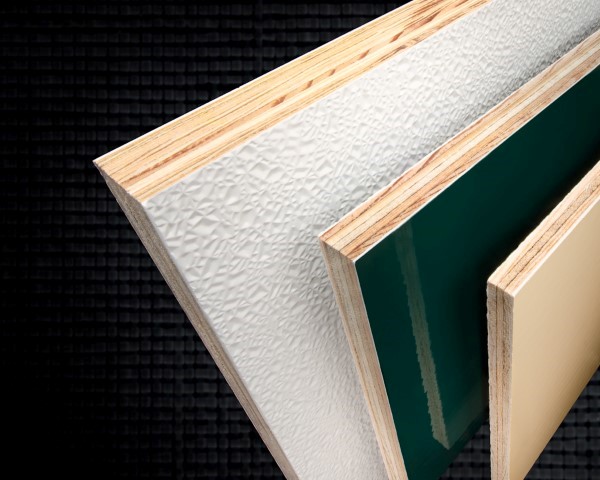

With the numerous strength and performance benefits of fiberglass fabrics, polyester gel coats, polyester thermoset resins, and structural exterior grade plywood or polypropylene honeycomb, Fiber-Tech can produce a one-piece, aesthetically pleasing, extremely durable, and long-lasting FRP panels at an affordable and competitive price.

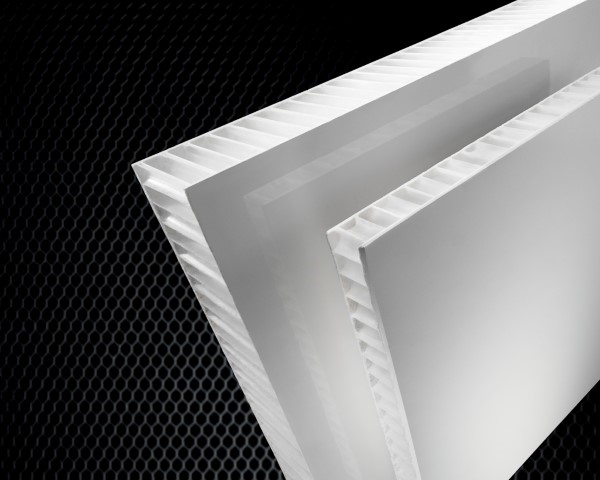

Plywood core materials have provided the “best bang for the buck” for many years. The exterior grade adhesives, combined with the American Plywood Association’s (APA) rated, type 1, structural 1, veneers, will provide years of service at a lower life cycle cost than most other core materials and wall systems. As an alternative, polypropylene honeycomb fiberglass panels fulfill the need of structural and durable panels at approximately one-half the weight of plywood cored FRP panels.

Fiberglass Panels For All Industries

Fiberglass has been widely accepted in the transportation, marine, military, corrosion, and construction industries for decades. Regardless of size, Fiber-Tech’s fiberglass panels deliver the strength and performance required for almost every type of composite panel design.

The plywood core is manufactured to Fiber-Tech’s specifications by the most recognized plywood mills in the nation. This is what creates the lightweight nature of fiberglass panels. Utilizing this core material in our unique process allow us to use polyester resin in its liquid state to saturate both the core and the woven roving fiberglass at the same time. This process overcomes the risk of delamination that can occur with other types of laminated cores using contact adhesives or glued skins.

The woven roving fiberglass is the strengthening or structural member of the composite FRP panel. The basket weave pattern of the woven roving fiberglass fabric compared to a random chopped glass found in other laminates, provides superior resistance to damage from impact and flexural movement. This pattern allows our fiberglass panels to have more strength and durability compared to our competitors' products.

UV stable polyester gel coat paint is bonded to the surface of the FRP panel at the same time as the polyester resin, which through wetted-out the woven glass, is curing into its hardened plastic state. This process takes place under heat and vacuum to ensure complete wet out of the woven roving fiberglass, the scrim, and the gel coat to produce a one-piece Fiber-Tech structural FRP panel.

Other panels available in the marketplace are produced by using adhesives to bond skins to either side of a substrate. Using an adhesive to bond three different materials together in a pinch roller or press does not produce the strength and quality of panel consistent with Fiber-Tech’s wet lay-up structural fiberglass panel.

FRP Panel Options

Fiber-Tech can produce FRP panels up to 10 feet wide by 58 feet long. Maximum thicknesses are dependent on the type of panel being built. For example…

- CladTuff®

- Plywood cores: 1/4” to 1-1/2”

- CladFoam® Insulated Fiberglass Panels

- Plywood/foam/plywood: 1” to 4”

- Lightweight Foams & Honeycombs

- Foams: 1/2” to 3”

- Honeycombs: 5mm to 102mm

- Solid Core Composite Laminates

- NIJ & UL Armor Ballistic

- Panels: 1/4” to 1.5”

- Corrosion Resistant Solid Panels: 1/4” to 1-1/4”

Contact Fiber-Tech Today for FRP Panels and More!

Contact Fiber-Tech today to learn more about the wide variety of FRP panels to perfectly fit your panel needs. Fiber-Tech is the leading manufacturer of fiberglass panels for the transportation, construction, corrosion, military, shelter and marine markets.

Call the “Composite Panel People”at Fiber-Tech Industries today!