Corrosion Resistant Fiberglass Laminates

Fiberglass Reinforced Plastic (FRP) has been used for industrial application since the 1960's. Adapted from the marine industry, FRP was first used for seawater and other corrosive applications like those found in pulp & paper industry. Today FRP is a proven construction material for extremely harsh environments in mining, mineral processing, chemical processing, and waste water treatment. Equipment uses include tanks, vessels, scrubbers, stacks & chimney liners, piping, duct systems and other miscellaneous equipment in corrosive environments. FRP is a proven material used in corrosive resistant construction with numerous documented successful case histories. Where metals reach their limits for chemical resistance, maintenance issues, or economic reasons, FRP should be your first choice. FRP panels are lightweight, corrosion-resistant, and above all, virtually maintenance free.

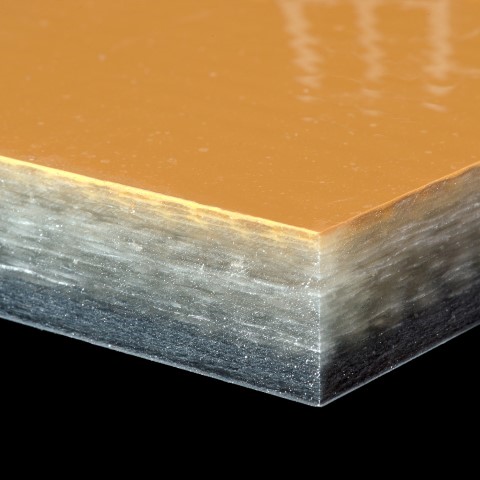

FRP Panels for Corrosion Resistance

Utilizing specialty formulated resins, Fiber-Tech’s solid panels provide industry with a fiberglass alternative to limited supply, expensive and exotic metals. Additionally, a combination of E-glass and C-glass plus chemical additives can be specially mixed into the resin system to provide additional solutions for…

- Corrosion resistance

- Flame & smoke resistance

- Abrasion resistance

- Conductivity & static electricity management

Advantages of Fiberglass Reinforced Panels for Chemical Resistance

Fiber-Tech’s FRP is highly resistance to most of the chemicals used today and will not crack, chip, peel, rust, rot or decay. FRP is pound for pound stronger than steel. Due to its lighter weight FRP requires less costly construction equipment is needed to complete the job. Fiberglass has become the product of choice for numerous industries. You will find Fiber-Tech’s panels in the chemical, mining, mineral processing, pulp & paper, and power industries in a wide variety of applications such as:

- Flue gas desulphurization scrubbers & absorption towers

- Stack liners

- Ventilation & duct systems

- Cooling water transmission

- Waste water containment

Fiber-Tech’s ability to produce the industry’s largest corrosion resistant panels allows the contractor & installer to reduce labor costs by reducing the quantity of field joints/seams. Less time at the job site equals lower installation costs and equipment downtime.

Contact Fiber-Tech Today for Custom Fiberglass Panels

Call today to learn more about the wide variety of panels to perfectly fit all of your insulated structural panel requirements. Fiber-Tech is the leading manufacturer of fiberglass panels for the transportation, construction, corrosion, military, shelter and marine markets.

Call the “Composite Panel People”at Fiber-Tech Industries today! Download Information Sheet