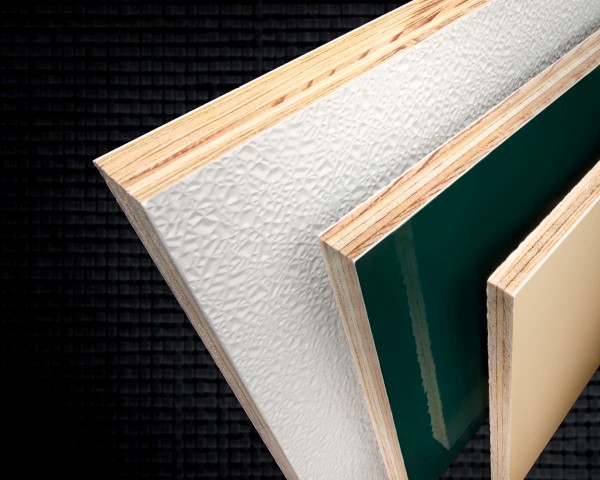

FiberForm® Fiberglass Reinforced Concrete Form Panels

FiberForm® Fiberglass Reinforced Concrete Form panels utilize a high quality APA trademarked Douglas Fir plywood core laminated with 17 oz. fiberglass woven roving to provide a high strength, durable, and reusable panel. The exterior of the panel is finished with a chemical resistant gel coat finish to produce a consistent high quality architectural grade concrete finish.

Advantages of FiberForm® Fiberglass Reinforced Concrete Panels

FiberForm® Concrete Form Panels are:

- Less expensive than steel forms

- More durable than MDO and HDO

- Known for providing high strength and stiffness

All panels custom cut to your specifications. Standard panel sizes can range from 4’ X 8’ or up to a maximum of 120” high X 58’ long at no extra cost per square foot. Longer panels have proven to offer superior consistency when building seamless curved forms. No job is too small or too large.

A typical Fiber-Tech FiberForm® panel uses APA trademarked B-CX plywood, plugged and touched sanded with Structural group I veneers to ensure smooth consistent concrete form panels. FiberForm® concrete forms are typically manufactured with 1/2”, 5/8” or 3/4” cores.

Fiber-Tech offers standard woven roving in either 17 oz. or 22 oz weights. Multiple layers of fiberglass can be laminated together to increase strength and further improve impact resistance.

FiberForm® panels are edge-coated with a water-resistant edge coating to prevent moisture absorption. FiberForm® panels exterior finish has been tested to be compatible with most releasing agents of various bases, concentrations and dilutions when used according to release agent’s directions.

The standard FiberForm® finishes are…

- Side 1—Gel Coat. 15 mils (+-.003”) of a smooth, high gloss concrete grade gel coat designed to offer superior weathering characteristics and abrasion resistance. Fiber-Tech’s concrete grade gel coat is formulated to offer maximum flexibility, abrasion resistance and is acid and alkali resistant.

- Side 2—Gel Coat. 15 mils (+-.003”) of a smooth, high gloss marine grade gel coat designed to offer superior weathering characteristics and high durability.

The Fiber-Tech FiberForm® advantage is…

- Seamless, one-piece construction

- Consistent panel finish results in uniform concrete finish

- Less rework saves time and money

- Custom cut to your specifications

- Durable, strong & abrasion resistant

- Long panel and form life results in low cost per pour

- Edge-sealed to resist water absorption

- Easy to strip and clean ensuring reduced labor costs

- Decades of proven FRP performance

Fiber-Tech FRP is an unbeatable investment for large seamless pours. FRP is less expensive than steel forms, more durable than MDO/HDO, and has a high chemical resistance. One piece, seamless panels can be custom cut up to a maximum of 10' x 55', perfect for pre-cast concrete panel manufacturers.

Contact Fiber-Tech Today for Fiberglass Reinforced Concrete Solutions

Call today to learn more about how the FiberForm® panel can save you time and money on the next major pour. Fiber-Tech is the leading manufacturer of fiberglass panels for the transportation, construction, corrosion, military, shelter and marine markets.

Call the “Composite Panel People”at Fiber-Tech Industries today! Download Information Sheet