Transportation Applications

Fiber-Tech’s fiberglass reinforced plastic panels are extremely durable and lightweight. Our FRP composite panels have been successfully used in the transportation industry for almost 50 years. The most common applications in high quality truck body and trailers are…

Truck Bodies

- Dry freight & reefers

- Sidewalls

- Bulkheads

- Doors

- Floors

Trailers – Commercial & Specialty Trailers

- Sidewalls

- Bulkheads

- Doors

- Floors & ramps

- Roofs

Increase your profits with FRP's ability to increase truck & trailer cubage. Fiber-Tech FRP trailers require no internal posts, allowing the maximum possible cargo capacity. In a typical 48-foot trailer, this means an extra 7 cubic feet of cargo space. When Fiber-Tech's Stratoply Super Roof® is used with our seamless sidewalls, another 17 cubic feet of space is realized. Increased cargo space will generate increased revenue making Fiber-Tech panels well worth the initial investment.

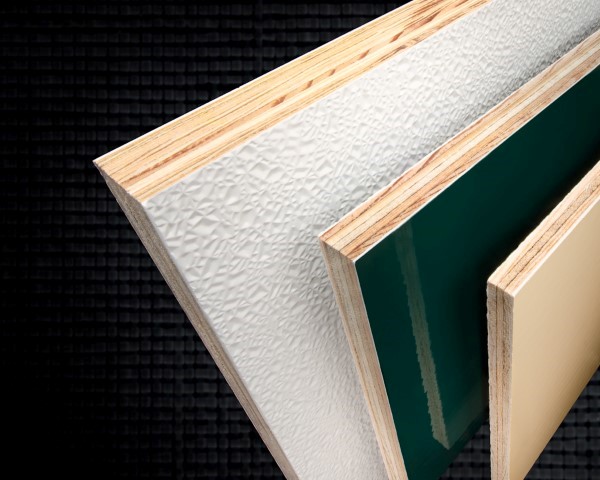

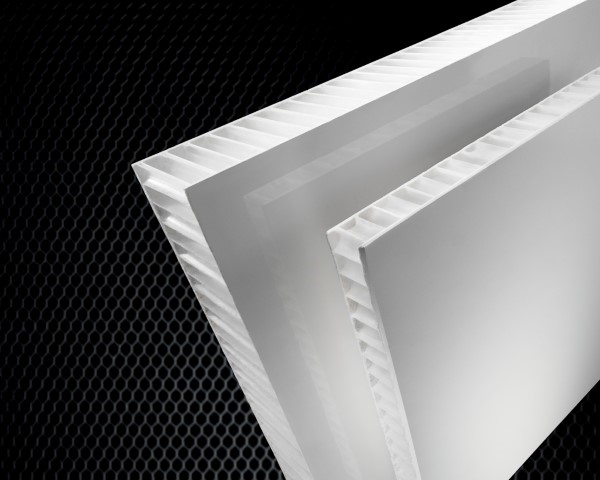

Core thickness ranges from 1/4" to 3/4" for standard FRP, and foam panels can be built up to 4.5" thick. Panel heights up to 120" and lengths up to 696" can be ordered with a wide variety of interior and exterior surface finishes.

| FRP Offers Real Savings in Transportation | ||

|---|---|---|

| FEATURES | BENEFITS | SAVINGS |

| FRP trailers are versatile. | The inherent insulating properties & corrosive resistance add cargo flexibility. | Versatility reduces dead heading and sitting times. More payloads = more profits. |

| FRP is tough. | More impact resistant than aluminum. | Longer life cycle. |

| FRP resists damage. | Easier to repair. Ask to see FTI's repair manual. | Save up to 80% annually on exterior and interior repairs. |

| FRP fights cargo damage. | Smooth interior surfaces do not snag or impact cargo. | Reduced freight claims = more profits. |

| FRP means more cubage. | Eliminates posts and plywood liners. | More freight per load. Approx 94 cu. ft per 48 foot trailer. |

| FRP is easy to clean. | More difficult for dirt and moisture to hold on. Steam cleanable. | Fast cleaning = shorter turn-around time. |

| FRP is corrosive resistant. | Absolutely won’t rust. Resists deterioration from rain, salt, sun and chemicals. | Better appearance. Longer life. Fewer repairs. |

| FRP exteriors are smooth. | Wind tunnel tests show a smooth exterior is 12% easier to pull than exterior post trailers. | Lower fuel costs. Less wear and tear on parts. |

Fiber-Tech’s fiberglass reinforced plastic FRP have proven their strength and durability over decades of time and millions of miles.

Call today to learn more about the wide variety of panels to perfectly fit all of your transportation panel requirements. Fiber-Tech is the leading manufacturer of fiberglass panels for the transportation, construction, corrosion, military, shelter and marine markets.

Call the “Composite Panel People”at Fiber-Tech Industries today!

Download Information Sheet for CLAD TUFF® FRP/Plywood Panels

Download Information Sheet for CLAD FOAM® Insulated Foam Core Panels

Download Information Sheet for Honeycomb Core FRP Panels

Download Information Sheet for Ribbed Foam Core FRP Panels

Download Information Sheet for STRATOPLY Super Roof