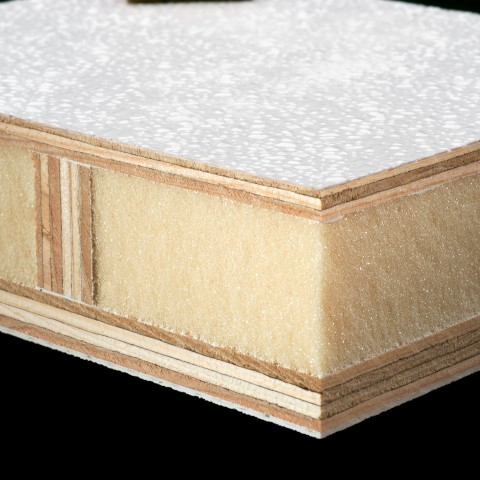

CladFoam® Polyisocyanurate Foam Core Structural Panels

Consider Fiber-Tech’s structural insulated fiberglass panels when your project requires strength, durability and superior exterior/interior finishes in a one-piece panel design. It is the true structural sandwich panel.

Standard CladFoam® panels provide maximum thermal efficiency by utilizing a polyisocyanurate foam during Fiber-Tech’s custom manufacturing process, producing a superior structural fiberglass panel with insulating and sound deadening properties. This custom fiberglass panel is a perfect sandwich for any insulated wall panel application.

Core materials come in thicknesses from 1/2" to 4". All panels are reinforced with either 17 oz. or 22 oz. woven roving and the exterior coated with high gloss gel coat. Interior surfaces can also be coated with gel coat for additional protection and cosmetic appeal. For additional strength, 3/4" stiffeners running vertically through the panel are integrated at 24" centers. CladFoam® panels are available in sizes up to 10 feet by 45 feet with a maximum overall thickness of 5”.

Design the Custom Fiberglass Panel for Your Application

Please review the typical and optional CladFoam® components below which will allow you to custom design an insulated panel to specifically fit your application.

CLADFOAM® Components:

Polyisocyanurate Foam. Fiber-Tech typically uses nominal 2# density, polyisocyanurate foam, sometimes referred as iso foam or urethane foam, for maximum thermal efficiency. Foam is available in thicknesses from ½” to 4”. Higher densities of foam are also available on special request.

Optional EPS or PVC Foams. Fiber-Tech also offers the choice of low to medium density expanded polystyrene (EPS) foam and PVC foam core materials. Principle benefits include increased impact resistance, adhesion and thermal stability. Foam thicknesses are available from ½” to 4”.

Plywood. Fiber-Tech primarily utilizes APA trademarked B-CX plywood, plugged and touched sanded one side, structural group I veneers.

Optional Polypropylene Honeycomb. A wide variety of thicknesses of honeycomb cores can be substituted for the plywood to significantly reduce the overall weight of the finished panel.

Fiberglass Reinforcements. Fiber-Tech offers standard woven roving in either 17oz. or 22oz. weights as well as 1.0 ounce or 1.5 ounce chopped strand mats.

EXTERIOR FINISH

Gel Coat. 15 mils (± .003”) of a smooth, high gloss gel coat provide excellent weathering characteristics and resistance to UV degradation. All standard Fiber-Tech gel coats are formulated to offer good flexibility, are acid and alkali resistant, and when the surface is properly prepared will readily accept decals and most paints. Please refer to Fiber-Tech's Limited Warranty and discuss your paint or graphic package intentions with our sales staff.

INTERIOR FINISHES

Standard Clear film. A thin clear film is laminated to the interior surface of the panel during the composite panel production process. This heat sealable film covers typical porosity and provides a surface which is considerably easier to clean than raw resin surfaces.

Optional Resin Surface. For applications where sanding, laminating, or bonding to the interior

surface of the panel is required Fiber-Tech can eliminate the use of the clear film. A white pigmented polyester resin will be the final interior finish and will contain porosity on the surface.

Optional Gel Coat. Where additional protection against moisture penetration is desired on the interior, Fiber-Tech will add 15 mils (+-.003”) of high gloss gel coat to the interior surface on special orders.

Optional – Sand/Aggregate non-slip textured finish surface coating: A post application of adhesive/resin with a sand aggregate distributed into the surface. A top-coat of an exterior latex paint is applied over the aggregate.

As you can see… a wide variety of options are available to achieve the desired strength, thickness or thermal value enabling you to easily custom specify your foam panel. At Fiber-Tech, you can choose…

- The desired CladTuff® or Honeycomb thickness and finish for the exterior side of the laminate.

- The desired type and thickness of the foam core.

- The CladTuff® or Honeycomb thickness and finish for the interior side of the laminate.

- The desired finish on interior and exterior of the panel.

Fiberglass has been widely accepted in the transportation, marine, military and construction, corrosion and marine industries for decades. These same benefits are recognized today in the construction of all types of refrigerated trailers, truck bodies, containers, storage containers, shelters, and walk-in coolers as the most durable and economical panel design.

Contact Fiber-Tech Today for Custom Fiberglass Panels

Call today to learn more about the wide variety of panels to perfectly fit all of your insulated structural panel requirements. Fiber-Tech is the leading manufacturer of fiberglass panels for the transportation, construction, corrosion, military, shelter and marine markets.

Call the “Composite Panel People”at Fiber-Tech Industries today! Download Information Sheet