FRP Panel Options

Fiberglass Reinforced Panel (FRP) Options

Exterior & Interior Panel Finishes

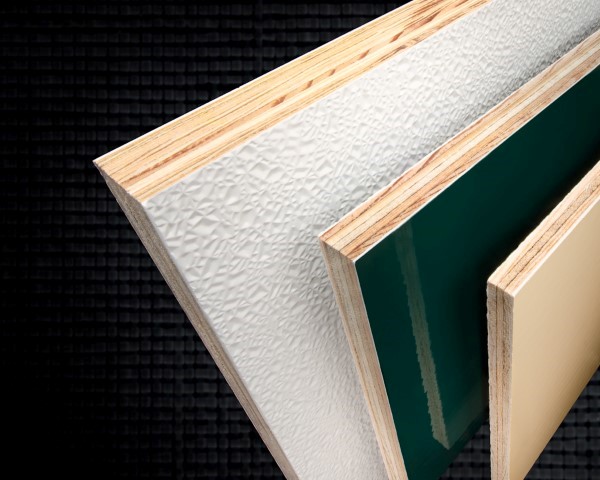

Exterior grade polyester gel coats are the most common finish in today’s fiberglass reinforced panels. Gel coats can be color-matched to almost any color in the rainbow. All standard Fiber-Tech gel coats for FRP panels are formulated to offer good UV & weather resistance, flexibility, and are resistant to most common chemicals. Premium grade gel coats are available on special request when extraordinary conditions exist. Contact Fiber-Tech if you suspect your fiberglass reinforced panel will be exposed to extremely severe and harsh conditions.

You can choose from a wide variety of interior panel surfaces. Standard white gel coat, white pigmented resin under a clear film, or a plain resin finish provide a wide range of finishes to suit your specific fiberglass panel application.

Upon special request a Pebble Grain gel coat finish is also available on one side of most Fiber-Tech FRP panels.

Fiberglass Woven Roving & Chopped Strand Mats

One layer of 17 ounces per square yard woven roving fiberglass is the typical reinforcement used in most Fiber-Tech FRP panels. You always have the option of increasing the weight of fiberglass by using an optional 22 ounces per square yard woven roving, or adding additional layers of woven roving. One ounce per square foot or 1.5 ounce per square foot chopped strand mat (CSM) can also be used if your project requires.

Edge Treatment

An optional edge coating can be applied to each FRP panel prior to shipment to protect the FRP panels in transit, or during temporary storage. See Fiber-Tech’s Product Info Bulletin - Storage & Handling FRP

Interior Scuff Protection

Fiber-Tech offers one or two additional layers of glass that can be added to our fiberglass reinforced panels, to give extra protection against mechanical damage. The option of a post-applied bonded FRP scuff is also available.

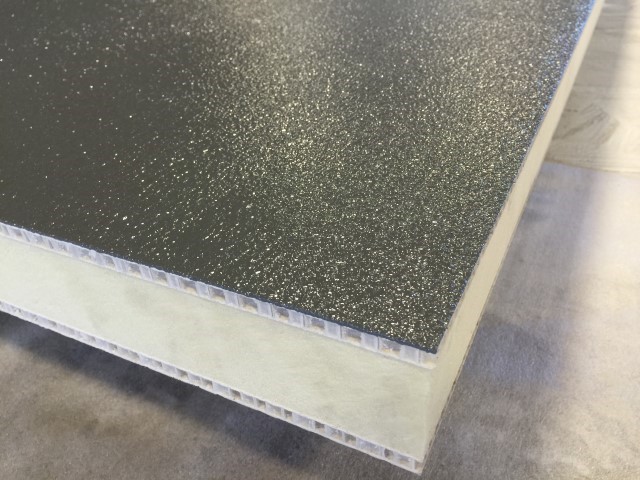

FRP Floors & Post-Applied Aggregate Coatings

A post-applied aggregate coating can be applied to any Fiber-Tech fiberglass reinforced panel to provide a non-skid or reduced-skid traffic surface. The wide variety of core materials, thicknesses and panel designs available in CladTuff® & CladFoam® FRP provide an almost endless opportunity for one-piece, seamless, walkable non-slip flooring options.

Contact Fiber-Tech Today for FRP Panel Options

Call today to explore your custom panel options to perfectly fit your project requirements and panel needs.

Call the “Composite Panel People”at Fiber-Tech Industries today!

- Download Information Sheet for CLAD TUFF® FRP/Plywood Panels

- Download Information Sheet for CLAD FOAM® Insulated Foam Core Panels

- Download Information Sheet for Honeycomb Core FRP Panels

- Download Information Sheet for Ribbed Foam Core FRP Panels

- Download Info Bulletin for Storage and Handling of Fiberglass Reinforced Panels