Containers – Shipping / Storage / Work / Military

Containers of all shapes and sizes:

Thousands of mobile storage containers and shelters have been built using Fiber-Tech’s fiberglass reinforced composite panels. This type of use requires the panels be attractive and extremely durable. Fiber-Tech’s structural FRP panels provide a one-piece seamless wall style of construction to not only reduce the cost of the initial construction, but also to provide years of savings due to the moisture resistant and maintenance free fiberglass construction. Fiberglass panels won’t rust, rot, or corrode which makes them perfect sidewalls, doors, floors, and roofs. Fiber-Tech’s smooth fiberglass reinforced finish doesn’t have seams or rough edges that can snag, shred or tear bags, cartons, cargo or other interior contents of the finished container.

- Shipping containers for land, air or sea

- Moving & storage containers

- Temporary work stations

- Military applications are endless

Whether you are building brand new containers from “scratch” or converting used steel shipping containers into more pleasing uses such as hospitality units, mobile offices, and work stations, Fiber-Tech has the solution for you.

Today, Fiber-Tech utilizes increasingly complex materials to produce structural composite panels that are lighter, stronger, more weather-resistant and extremely adaptable for use in a variety of commercial and industrial applications.

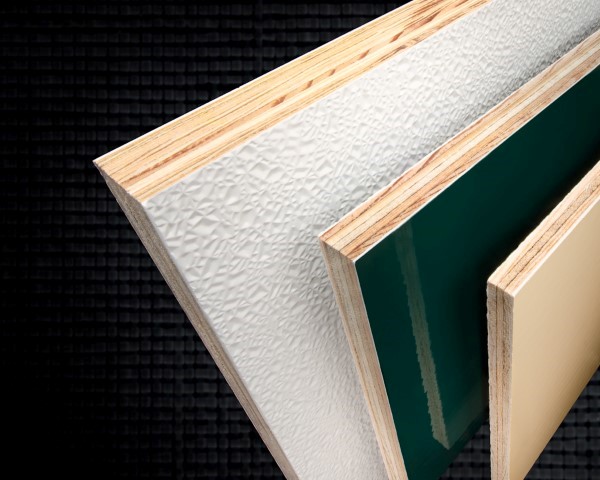

Our unique manufacturing process begins with a broad range of substrates / core materials, reinforcements and bonding resins selected to create the optimal panel for your specific application. Fused together under carefully controlled, uniform heat and pressure, the composites unite to form smooth seamless structural panels, which do not require painting or surface finishing.

Select standard CladTuff® panels for economic strength and durability, CladFoam® structural panels when increased strength and insulation R-value is required, and foam or honeycomb panels when lightweight construction is the driving factor. Fiber-Tech’s capabilities are flexible enough to help you realize your full potential for any project.

Contact Fiber-Tech Today for FRP Panels

Whether your application calls for flat panels made with plastic, fiberglass, plywood, or other specialized materials, Fiber-Tech has the experience and expertise to create the products you need.

Call the “Composite Panel People”at Fiber-Tech Industries today!

Download Information Sheet for CLAD TUFF® FRP/Plywood Panels

Download Information Sheet for CLAD FOAM® Insulated Foam Core Panels

Download Information Sheet for Honeycomb Core FRP Panels

Download Information Sheet for Ribbed Foam Core FRP Panels

Download Information Sheet for ARMOR BALLISTIC Fiberglass Panels